This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

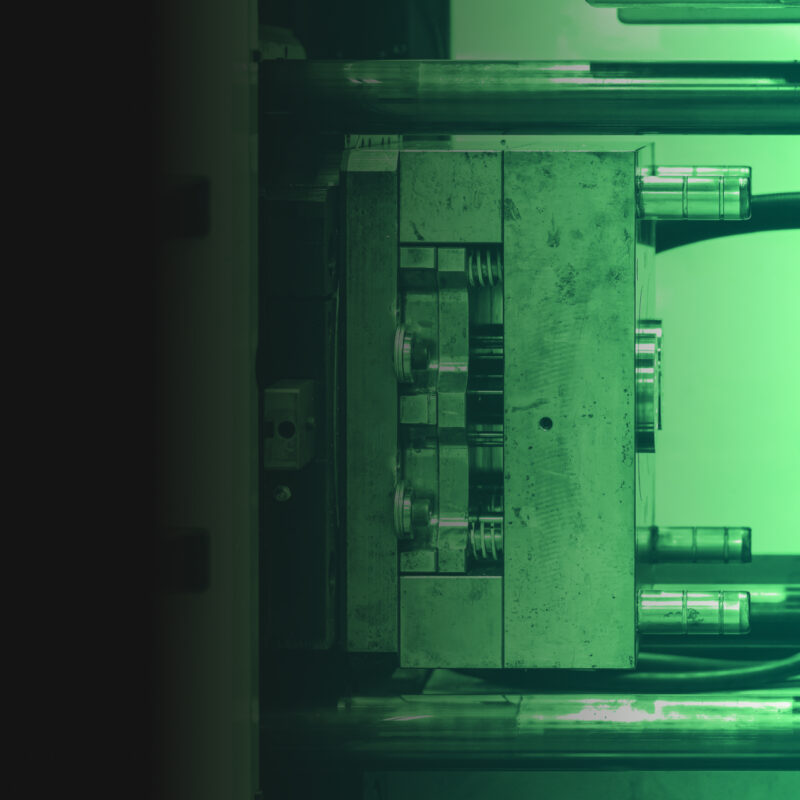

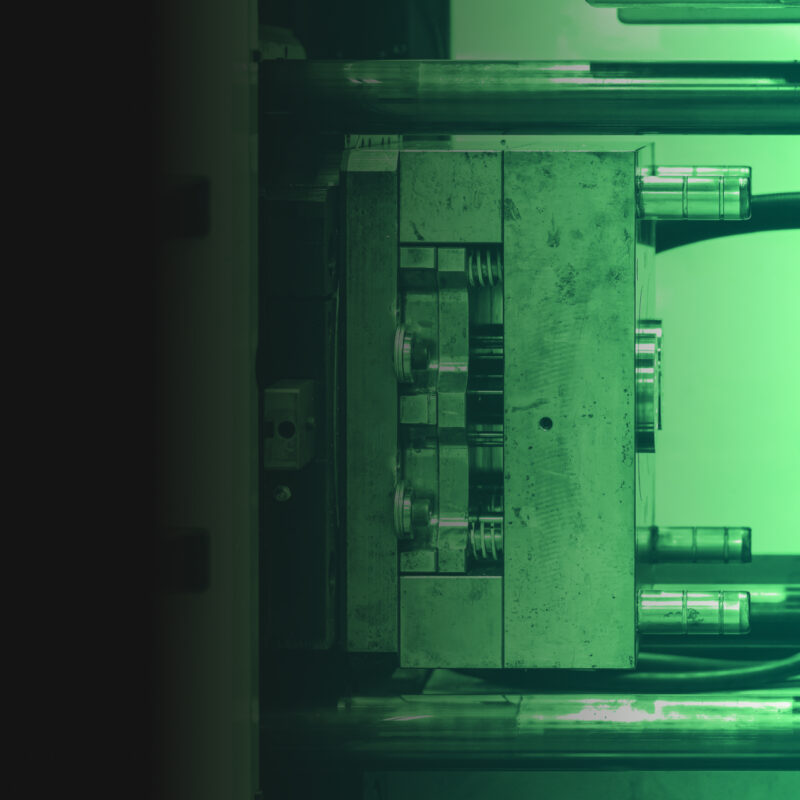

Intricate and bespoke, high quality injection moulding.

Our Injection Moulding Services

We offer a broad range of plastic components through injection moulding. Additional services include engineering tool design, secondary operations, and assembly.

Regardless of your industry, whether it’s automotive, medical, consumer goods, or any other sector, we possess the knowledge and capabilities to cater to your precise injection moulding requirements.

Our Materials

We manufacture high quality moulded products in a variety of plastics and complex engineering polymers. For example:

- With flame retardant properties

- Polypropylenes

- Acetal Acrylic resins

- Recycled plastics

- Nylon

- Biodegradables

Our Sizing

We can produce a wide range of product or part sizes, from tiny to 2kg. We have 11 moulding machines with:

- 22-320 ton clamp force

- 22-320 ton locking force

- 1g-1.5kg shot weights

Our Machines & Equipment

We have 11 moulding machines with clamp force ranging from 1 to 300 tons with shot weights between 1g and 2kg.

Whatever your injection moulding requirements, or deadline,

MTM are here to support.

High Quality Components

- We manufacture high quality moulded products in a variety of plastics and complex engineering polymers.

- We can advise on optimised shot sizes of moulding to reduce cost but retain quality.

Unique Moulding

- We offer rapid tooling and can turn around the most unique moulds.

- Our production process and exact design will vary depending on application, industry and regulation.

Tool Design

- We can advise on tool design or troubleshoot issues with existing components.

- We offer a full tool inspection and refurbishment service as well as repair.

Our Assembly Process

The assembling of components to make a complete product or part is a crucial step in the manufacturing process.

We offer this service to all our customers, whether injection moulded plastic parts or machined metal.

Our assembly team has decades of experience creating production lines that ensure efficiency, quality and speed.

All your tooling needs covered

This service is carried out on site by our expert engineers with decades of knowledge.

We are open to tools from all regions of the world, as well as the UK.

Advise on new tool design and troubleshoot issues with existing tool design.

Offer a full tool inspection and refurbishment service, as well as repair.

Advise on optimised shot sizes of moulding to reduce cost, but retain quality.