This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Precision machined, engineering components.

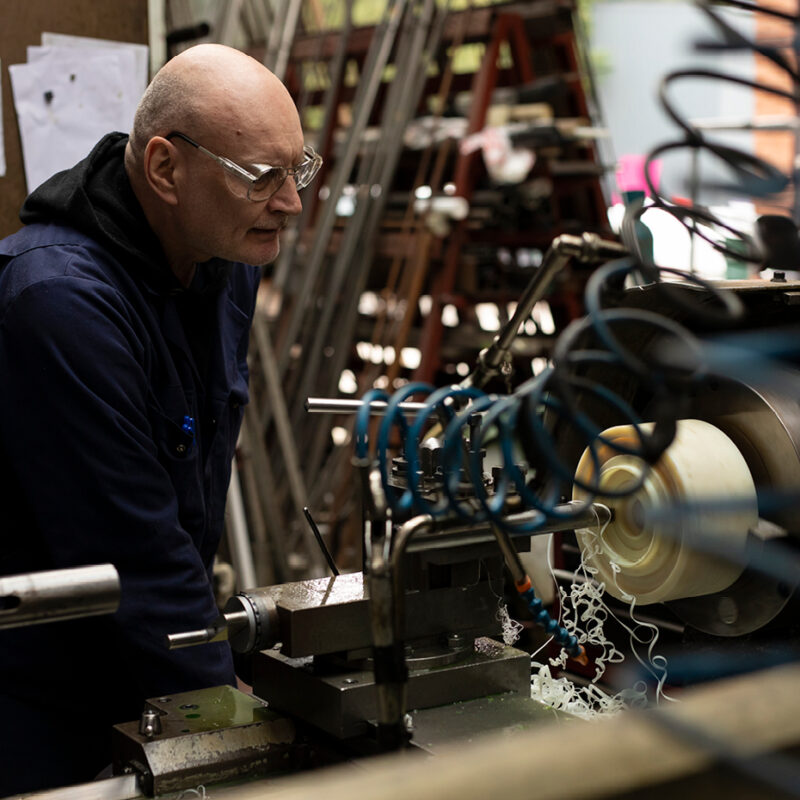

Precision Machining

MTM manufactures parts ranging from standard products to extremely intricate high tolerance components.

Milling (Manual/Automatic/CNC)

CNC

Turning (Precision/Production/Auto/CNC)

Grinding/Re-Grinding (Surface/Tool)

Assembly

Tool Making

Bespoke CNC Components

We offer rapid tooling and can turn around the most unique components.

This image shows a bespoke precision machined CNC component, designed, and engineered for a major food ingredient manufacturer. A quick release shaft that saves time and money by enabling the customer to interchange different feed operations with minimal waste.

Our Materials

We work with a large array of ferrous and nonferrous metals, along with various types of plastic, depending on your exact requirements.

Metals include:

- Steel and Stainless Steel

- Cast Iron

- Brass

- Copper

- Aluminium

Our Work

From prototyping bespoke parts to volume production, our flexibility allows us to offer a varied service to suit any requirements.

Below are a few bespoke components to illustrate our capability, give us a call to discuss your specific milling, CNC and precision turning needs.

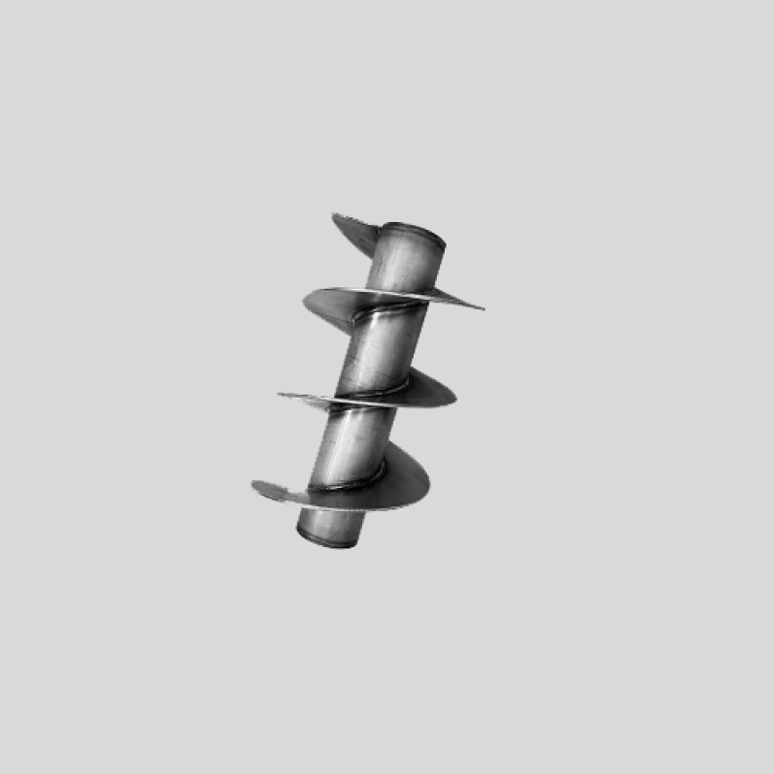

Feed Worm

We engineer this for a customer in the food industry who uses it to mix ingredients on an industrial scale. The complex and intricate geometry of this part is produced with consistent quality and dimensional accuracy across large product runs.

Bearing Bush

This Bush is part of a quick release shaft is used in a chemical powder machine. When combined with a cylindrical sleeve, it reduces friction and wear between rotating or sliding surfaces and helps evenly transmit load.

Adaptor

With very detailed high tolerance leads inside this adaptor, and very high tolerance internal grooves this part is extremely intricate to produce from an engineering perspective.

Light Fitting Components

These are components for lighting systems. Once powder coated, they will be installed into display cabinets. Each element has very high tolerance so precision is key.

Gear Stick

When assembled, this will be a gear stick for the bespoke car market. This specialist design is machined out of aluminium with a high tolerance and custom finish. Perfect for the discerning car enthusiast.

Brass Screw

This is a brass screw for the top of a bespoke real ale pump. A very important job I’m sure you agree. At MTM we can machine any metal to suit your requirements and finish.

Our Assembly Process

Creating finished parts from various individual components is a key service we offer whether for machined metal or plastic parts.

Our assembly lines are bespoke by product and designed to ensure maximum efficiency, quality and speed.

After Market

Our after-market support is distinguished by its ability to cater to low volume needs with a rapid turnaround.

Whether it’s spare parts, technical assistance, or maintenance, we ensure that we’re able to support your unique requirements promptly and efficiently, solidifying our commitment to customer satisfaction.

Get in touch